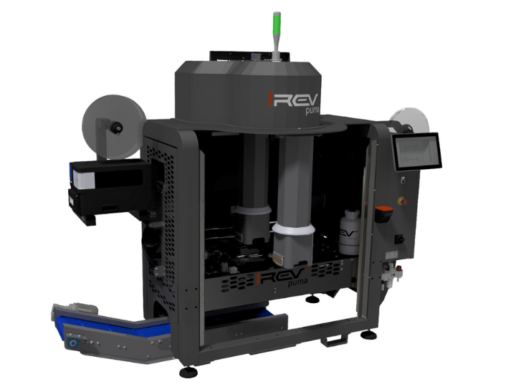

PUMA

THERMOSEALING NETTING MACHINE

CREATING 100%-RECYCLABLE MONOMATERIAL PACKAGES

USING 50% LESS PLASTIC EACH PACKAGE

ENSURING HIGH PRODUCTION CONTINUITY

EXTREMELY FAST AND RELIABLE

- Puma is an automatic vertical netting machine for packaging products in bag with no metal clip: the package, P-Pack, is made of tubular net, either woven or extruded, sealed with a label, and of a ribbon functioning as a handle. The label can be weld-to-weld (sealed at the extremities) or wineglass type (in both cases, it is customisable in shape and is realised my means of pre-registered printing).

- The machine, in fact, is equipped with a thermal-transfer printer capable of operating directly on the label, either on the inside or the outside, as well as with high-quality and -technology components: the wide touch-screen display allows to programme various production recipes, for an easy use. Moreover, thanks to the two net tubes with automatic change, Puma ensures high production continuity.

- REV can provide the packaging materials, which can be in PE or compostable.

IDEAL FOR:

citruses, onions, potatoes, garlic, shallots, chestnuts, etc..

Do you need further information about our machines?

TECHNICAL FEATURES

- External structure in painted carbon steel

- Parts subject to cleaning in stainless steel, anodised aluminium and plastic

- Product-contact parts made of food-contact compliant materials

- Electrical cabinet 400 V 3P+N+PE 50 Hz

- Resettable fuses

- Motor thermal protections resettable from the operator panel

- Upstream signal

- Downstream signal

- 400 V electrical connection included in the emergency circuit of an elevator conveyor (optional)

- 15.6″ integrated all-in-one Windows PC with colour capacitive touch-screen control panel

- HMI R-Sense 2026

- Printer software management (Toshiba – optional) via integrated computer

- Advanced and exportable production statistics

- Interactive manual on display

- Multicolour signal tower with acoustic alarm

- Hot bar sealing with self-regulating intelligent algorithm

- Sealing heads with non-stick coating (for easier cleaning)

- Thermocouples with IP55 protection rating and integrated mechanical protection

- Overtemperature safety circuit

- Water-cooled sealing with 5-litre tank and level management with refill from outside (without stopping the machine)

- Product feeding hopper W670

- Automatic tube change (without stopping the machine)

- 2 octagonal net holding tubes Ø205 with friction ring Ø270

- Net loading cone

- Buffering flap

- Anti-jamming device for product at tube inlet

- Drop cushioning on guillotines

- Guillotine obstruction sensor

- Wineglass or weld-to-weld label applicator (W=40–100) with servo motor

- External printer connection (Toshiba BX410 with save-ribbon function – optional)

- Helical label track

- Label reel holder with adjustable centring device (W=40–100)

- Net unwinder with servo motors

- Handle strap unwinder W25 with servo motor

- Handle reel holder with external end-of-material sensor

- Bag drop cushioning with servo motor

- Servo motors with IP65 protection rating

- Safety light curtains, 14 mm pitch (no access doors)

- Air system with safety valve

- Air gun for sanitisation

- Digital pressure gauge with integrated pressure switch

- Outfeed conveyor for finished packages (adjustable orientation)

- QR code for quick access to technical documentation

- Service kit: high-temperature brush, maintenance and wear parts

- Remote assistance

OPTIONS

- Net tubes available in different diameters, according to the product and the package

- “V” product-in-line-infeed conveyor (instead of the hopper)

- Easy Remote teleassistance

- Integration into SCADA systems

- 4.0 interconnection