6+6 LINEARPACK

ULTRA-GENTLE WEIGHER WITH LINEAR PACKAGING STATION

PRECISE

ULTRA-GENTLE

EXTRA-VERSATILE

SANITISABLE (IP65)

- Ultra-gentle manual-loading combination weigher, suitable for preparing doses according to a pre-arranged (and never lower) weight. Products are placed by operators on pre-load conveyor belts (optional, intended for maximising the machine performances) or directly on weighing belts, with the help of lights indicating the proper quantity of product. Thus, the computer calculates the best combination possible for composing the dose. Products then pass from the scale to the central conveyor belt and are ejected without being dropped from above.

- Equipped with smart functions, settable from the touch-screen panel.

- Highly engineered: the structure is solid and built with state-of-the-art technologies and high-level components. The weighing belts are removable in a few seconds without using tools and all parts are easily accessible for maintenance, without compromising the operator’s safety.

- Extra-versatile: extremely compact, thus suitable for small spaces, 6+6 is easily movable thanks to its wheels and loading / unloading slots. Widely customisable, then, it is adaptable to all pre-existing lines, it can be combined with several devices (such as conveyor belts and hoppers) and coupled with different packaging machines (e.g. netting machines, flow pack machines, stretch machines). All of that, makes 6+6 indicated for different types of products and sectors.

- Economic return is guaranteed quickly: giveaway is reduced to a minimum, as a consequence, 6+6 is particularly indicated for premium products. Moreover, thanks to the material used not subject to wear and tear, the machine will maintain its value over time. It does not require compressed air, thus there is no energetic waste. Also, maintenance costs will be really low. Finally, 6+6 is subject to Industry 4.0 financial benefits.

- Suitable for food contact, according to European regulations.

- Particularly easy to sanitise: fully in AISI 304 stainless steel and polymers, thanks to its IP65, it is completely washable by using water jets, without removing parts. The electrical wiring integrated into the main structure, further facilitates the machine sanitisation.

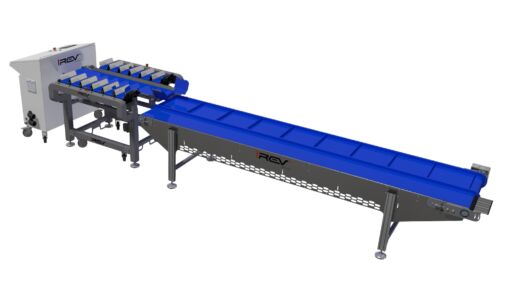

- The weigher has been designed to be paired with a manual packaging station, such as Linearpack. The linear layout of Linearpack, combined with intermittent movement, perfectly suits workflows that require a certain degree of separation between the weighing and packaging phases. Moreover, developed on a single level, it is particularly ergonomic and functional for the operator, who can work quickly and without interruptions. Each operator manages only the section positioned in front of him / her and handles a clearly defined phase of the filling / packaging process (thus the number of operators will vary depending on the number of phases needed to complete each package); the punnet therefore advances without the need for further handling. The intermittent movement also ensures that the production process is more orderly and the output more consistent. All of this ensures maximum efficiency and makes Linearpack ideal for high-productivity lines. Furthermore, the entire system provides numerous other advantages: the simplicity of the operator’s actions reduces fatigue, and the operator has time to check product quality. Finally, thanks to its design, Linearpack can be paired with an automatic punnet denester.

IDEAL FOR:

Products in bunches (such as tomatoes and grapes), leafy products (for example, cabbages and herbs), elongated products (courgettes, asparagus, green onions, leeks, etc.), and fruit and vegetables in general, including large ones (such as peppers), but also meat, fish, pet food, and anything that can be contained in the scales, whether fresh, frozen, wet, dehydrated, sticky, or vacuum-sealed.

Do you need further information about our machines?

TECHNICAL FEATURES

- 7” colour touch-screen control panel

- New intuitive R-Touch graphic interface with production statistics, exportable and viewable remotely

- Gentle outfeed conveyor belt with speed adjustment from recipe

- Count+Weight function (by means of product average weight)

- Speed- / Accuracy-balancing adjustment function

- Production mode in Grams (g) / Pounds (lb)

- Overweight check with acoustic signalling

- Outfeed conveyor belt with 3 modes: synchronized with the scales, moving, static

- 12 weighing belts

- IP65

- Division for each scale: 1 g (± 1 g)

- Tilted electrical panel on wheels, in IP65 painted steel

- Maximum product length: 320 mm

- Theoretical potentiality: more than 40 doses/min. (according to the operators’ skills, to the type of product and to the set accuracy and weight)

OPTIONS

- 12 pre-load conveyor belts for scale feeding

- Delta robot or cobot (collaborative robot) for scale feeding

- Central conveyor for product selection and infeed

- Custom discharge system (alternatively to Linearpack)

- Automatic punnet filler (alternatively to Linearpack)

- Rotopack Linear packaging station (alternatively to Linearpack)

- Automatic punnet denester

- Easy Remote teleassistance

- Integration into SCADA systems

- 4.0 interconnection