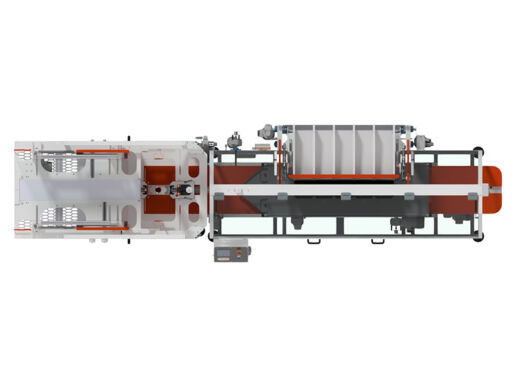

SUPERNOVA-SERIES V

GENTLE PUNNET DENESTER-FILLER

EXTREMELY VERSATILE

GENTLE AND FAST

EASILY SANITISABLE

HIGHLY AUTOMATED

- Automatic machine made of denester (Supernova) and filler (V5-203, for instance) for punnets and trays, projected for receiving doses ejected by weighers. It can also be combined with fruit counters or placed downstream of sorters.

- It can also be used the denester alone for feeding manual filling lines in which the operator only has to place the product inside the punnet.

- Series V fillers are projected specifically for delicate products; in fact, the outfeed does not happen by means of hoppers but through conveyor belts which ensure particularly reduced fallings and the least possible amount of impacts.

- The most versatile machine on the market. In fact, it works both carboard and plastic and it has been projected for all punnet types and sizes (traditional open ones, with wings and clamshells). Moreover, it can be easily set (under request) for the filling of small crates.

- It changes format in some minutes. It is possible to switch from one punnet type to another (for instance from cardboard trays to clamshells) in a few simple steps.

- Easily programmable with various recipes, according to the punnet and product to be worked. The most common settings have been reduced to a minimum, for facilitating the operator.

- Highly automated: the touch-screen panel allows to manage the machine smart movements with memory function; thus, the machine will be able to adjust itself according to the recipe set, in total autonomy, except from some manual controls to be carried out by means of the specific index knobs.

- Automatic punnet tank particularly wide which guarantees a high production continuity.

IDEAL FOR:

peaches, nectarines, kiwifruits, apricots, plums, tomatoes, avocados, cherries, apples, pears, etc..

Do you need further information about our machines?

TECHNICAL FEATURES

- 7” colour touch-screen control panel

- New intuitive R-Touch graphic interface with production statistics

- Single denester electro-pneumatically driven with high-performance servomotor

- Filling conveyors adjustable in height with memory function

- Filler with self-adjusting guides with memory function

- Vibrator for product settling

- Quick-release outfeed funnels according to the size of the punnet to be worked

- Outfeed conveyor with electronic speed management

- Multiple-conveyor simultaneous outfeed (conveyor amount and pitch to be defined)

- Smart warning signalling, without stopping the production

- Punnet sizes (positioned longitudinally): min 60×95 H30 mm / max 200×200 H150 mm

- Punnet sizes (positioned transversally): min 60×60 H30 mm / max 300×200 H150 mm

- Maximum punnet height with raised wings: 250 mm

- Approximate production: more than 80 packages/min. (strictly depending on the punnet features)

OPTIONS

- Additional outfeed funnels for punnets of different sizes

- Kit of clamshell-support guides

- Kit of wing-bending guides

- Different mounting configurations, according to the plant

- Easy Remote teleassistance

- Integration into SCADA systems

- 4.0 interconnection