SUN PACIFICTen lines for the packaging of kiwifruits

SUN PACIFIC10 Lines for the packaging of kiwifruits

THE COMPANY

Sun Pacific has born in California in 1969, as citrus producer and packager. Currently, the company is the most important producer of kiwifruits and citruses of all North America: with its 30000 acres of land and more than 75 million of fruit packages each year, Sun Pacific represents the supplier of the 50% of the total kiwi production in the USA.

THE REQUEST

The company needed to automate the kiwi packaging process, that up to that moment happened manually, as well as to package the kiwifruits in clamshells of different formats, with the purpose of becoming the first packager of kiwis in the USA, by minimising labour and increasing production.

OUR SOLUTION

REV projected and realised a packaging machinery customised according to the client’s needs, allowing to automate the clamshell weighing and filling and to independently and quickly change the format to be worked.

This represents a remarkable innovation with respect to previous systems that, for the format change, required a quite-expert operator and an elevated amount of mechanical operations which implicated long machine stops. On the contrary, the solutions realised by REV for Sun Pacific allow to easily modify the format, by means of fast and simple procedures.

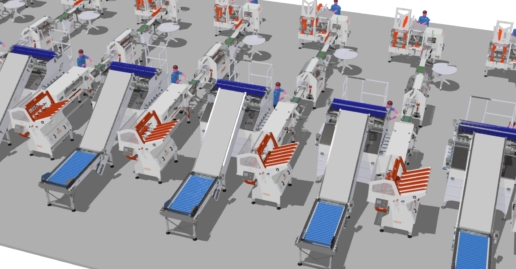

Once confirmed the satisfaction with the first line provided, during three years, the plant progressively expanded and, nowadays, it has, as a whole, ten lines, each one composed by:

- Bison weigher, extremely fast and gentle;

- U5-203 denester-filler, able to simultaneously work 5 punnets;

- Click clamshell closing machine, capable of closing 5 punnets each cycle (also specifically realised for Sun Pacific)

- C-Box checkweigher with diverter for verifying the weight of single punnets.

Each line guarantees a production of 60 punnets per minute (3600 in an hour).

At these lines have then been added two America crate fillers. In this case too REV specifically realised for Sun Pacific a machinery which, in contrast with other ones on the market, is programmable for working with 4-12 punnets per box, on one or two levels, in an automatic, simple and fast way, through the specific touch-screen display.

The machinery is integrated inside a SCADA (Supervisory Control And Data Acquisition) communication system capable of supervising in real time the functioning state, preventing and reducing potential machine stops and constantly checking the production levels.

BENEFITS

Thanks to the machinery realised by REV, Sun Pacific obtained different benefits:

- Production, to parity of operators, increased by 12 times (60 punnets/minute vs 5);

- The production costs related to labour decreased, saving up to 50%.

NEED

Automation of the kiwi packaging process, for North America’s main producer

SOLUTION

Customised packaging machinery which guarantees fast format changes

RESULTS

- Twelvefold increase of the production, to parity of operators

- Saving on the production costs related to manpower of more than 50%

Why REV

REV provides innovative solutions for packaging fruit and vegetables customised according to the specific needs of the packager, automating processes carried out manually, so far, and facilitating the format change, as in this case: our clients can witness the efficiency, great performances and sustainability of our machines.