The monomaterial alternative to metal clip

In REV, we boast a long experience in hot sealing and, for years, we have been committed to environmental respect. An example of this is provided by Puma, packaging machine for thermosealed nets which creates a 100%-recyclable monomaterial packaging consisting of tubular net.

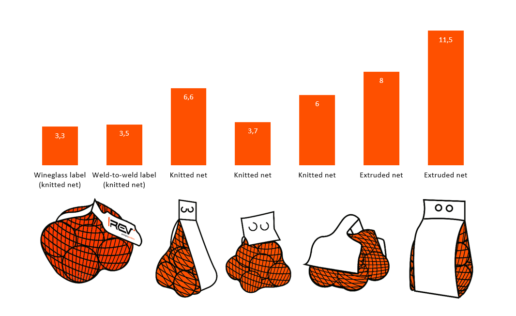

But there is more: unlike most thermosealing packaging machines on the market, Puma applies to the package a tape functioning as an handle and a label, wineglass or weld-to-weld (sealed at the extremities). Furthermore, the machine is equipped with a thermal-transfer printer capable of printing all product information directly on the label.

The label, customisable is shape and size, offers then a wide space for communication and guarantees an attractive and appealing package. All of that, simultaneously saving a significant amount of material: overall, Puma’s P-Pack is made with 50% less plastic than classic thermosealed bags!

Designed several years ago and optimised over time, Puma provides a valid alternative to metal clips without compromising on weight or packaging costs and ensures the efficiency of years of development and testing.

Puma is born with the aim of a recycling that may be economically sustainable and accessible to everyone, and not only to countries with the most advanced disposal facilities. It is therefore essential to create a monomaterial packaging.

Puma wins the challenge of replacing the metal clip with a solution that guarantees a packaging that is equally simple and lightweight, and therefore cheap for both the packager and the consumer, and has a lesser impact on the planet!