Packaging and Packaging Waste Regulation (PPWR)

What will change from 2026 for packaging and its disposal

In February 2025, the PPWR, Regulation (EU) 2025/40 on packaging and packaging waste, entered into force.

The regulation updates and complements the previous texts with some new provisions.

A step back: environmental labelling from the beginning

Environmental labelling, meaning the obligation to indicate the composition and methods of reuse and recycling on all packaging, has been discussed for decades.

This very sensitive issue has been addressed repeatedly:

- Since 2006, it has been mandatory to identify the material each package is made of, to provide clear instructions for recycling.

- In 2020, these indications were required to become clearer and more transparent for consumers as well, theoretically introducing a note on how to dispose of the packaging or an invitation to check with local regulations.

- In practice, however, disposal instructions were postponed multiple times and only became fully mandatory in 2023.

- So, what happens in 2025?

The new developments introduced by the PPWR

The 2025 PPWR establishes that labels must be standardised across the EU – a major step forward for consumers, who currently face unclear and inconsistent information.

To overcome the space limitations of physical labels, a digital format will also be adopted, which is QR codes to provide all relevant details.

From 12 August 2026, once the European Commission has defined (and hopefully explained) the standards of these harmonised labels, all packaging producers must comply with initial goals:

- demonstrate the exact composition of their packaging;

- reduce excessive weight and volume (no more than 50% empty space inside the packaging);

- eliminate hazardous substances from packaging and recycled materials;

- begin applying the principle of design for recycling, which requires that by 2030, all packaging on the market must be at least 70% recyclable.

Penalties will already be applied from 2026 for non-compliance with the initial objectives. In 2028, Harmonised and Digital Labelling will officially come into force, although a transition period will allow companies to sell off existing stocks.

But that’s not all: from 2029, in countries where recycling targets are not met, deposit return systems will be introduced to encourage the recycling of plastic and metal beverage containers.

And again, regarding plastic...

There is still talk of banning single-use plastics, even for unprocessed fruit and vegetables under 1.5 kg.

While this ban makes perfect sense for some products, it’s not appropriate for fresh produce.

Products that will definitely be banned include: ultralight plastic bags (unless used as primary packaging), baggage wrapping at airports, packaging for food and drinks consumed on site in hotels, restaurants and bars, disposable plates, cups and cutlery, and single-use cosmetics in the hospitality sector.

As for fruit and vegetables, no need to panic for now: each Country will define when plastic is strictly necessary for hygiene and safety reasons, and to avoid food waste. This principle will certainly apply to meat, cold cuts and fish – and hopefully also to tons of fruit and vegetables that would otherwise end up in the bin.

Checkweighing gets a blast with Dyno

Utmost precision at full speed

What is Dyno?

Dyno is a dynamic checkweigher designed to verify the weight of packaged products in motion, without stopping the production line.

The benefits of using a checkweigher

Checkweighing is not just a legal matter: it’s not only about complying with regulations that require declaring a minimum package weight, but above all, it’s beneficial for you!

Why give away your product when you can monitor and verify the exact weight of every single unit? Using a checkweigher is a great advantage for everyone – packagers and consumers.

Why choose Dyno?

Dyno’s technology is based on a weighing system with an optional separate diverter that eliminates vibrations on the scale, ensuring extremely precise measurement at any processing speed.

Moreover, Dyno is ultra-quiet, aesthetically really elegant, ergonomic and easy to use thanks to the touch-screen panel that simplifies the management of operational parameters. But there is more.

Built to last and offer the highest hygiene standards

Dyno is solid and robust, built with state-of-the-art components particularly resistant to wear, and features an IP65 protection rating that makes it very easy to sanitise.

Maintenance is also simple and immediate: the conveyor belts are removable without tools and every part is safely accessible.

What does this mean? Dyno is simply ideal for industrial environments where hygiene and durability are a must!

Freskon 2025: we were there, even if we weren’t

Thanks to those who thought of us

Freskon 2025 has just wrapped up, leaving behind three days full of meetings, exchanges and new developments in the world of fruit and vegetables and its packaging.

Unfortunately, we couldn’t attend in person this year, but we were there in spirit – thanks to our partner Soulis, who, as always, represented us at their best.

Many of you stopped by their stand, shared thoughts and ideas, we were told. We are truly grateful to everyone who thought of us, even from afar.

For now, we leave you with a few snapshots straight from Thessaloniki: even if we weren’t physically there, we definitely feel part of this edition. See you next time, Freskon!

Freskon 2025

A dive into the innovation of agricultural practices and packaging for fruits and vegetables

With the arrival of spring, the attention of fruit and vegetable industry professionals turns to Freskon. But what is Freskon?

Since 2015, Freskon, in Greece, has established itself as the leading trade fair for the fruit and vegetable sector in the Balkans and Southeastern Mediterranean, becoming a strategic bridge between companies involved in the distribution of fresh produce and global markets.

What to expect at Freskon 2025

Attending Freskon means immersing oneself in innovation. The fair provides a comprehensive overview of current and future market trends, along with valuable networking opportunities with participants from around the world.

This year’s edition, in particular, promises a rich and diverse program, featuring events and workshops dedicated to agricultural practices, preservation, packaging, commercial insights, and consumer behaviours.

Useful information

The event will take place at the Thessaloniki International Exhibition & Congress Center from April 10th to 12th, Thursday and Friday from 10:00 A.M. to 7:00 P.M., and Saturday from 10:00 A.M. to 5:00 P.M.

Once again, our partner Soulis will represent us. You can find them at Hall 15, Stand C01: come discover what we have prepared for you!

FRUIT LOGISTICA 2025: a memorable edition

Record numbers at Messe Berlin

FRUIT LOGISTICA 2025 has just concluded. We’ve just returned, and we at REV cannot wait to hit the road again!

However, we’d like to begin by sincerely thanking everyone who came to visit us: current and future clients, and all the new contacts. It is always a pleasure to personally share our work and discuss with those who share our passion for innovation in packaging for fruits and vegetables.

It was truly a valuable opportunity, and the numbers confirm it: 23500 representatives from exhibiting companies worldwide and 67500 visitors, totalling 91000 industry professionals, all gathered under the great roof of Messe Berlin to shape the future together. There’s no better slogan than “FRUITFUL CONNECTIONS”!

Here are some snapshots of what were the most significant moments for us during the event.

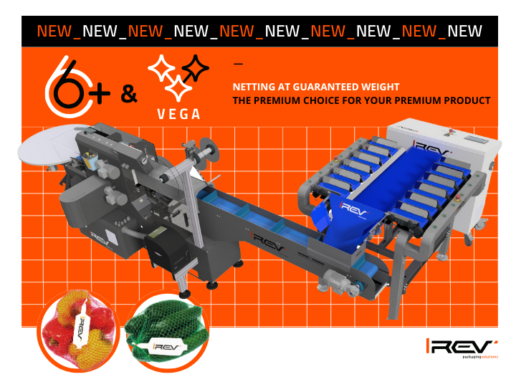

6+6 and Vega: smart revolution

Vega joins 6+6 for an even more efficient packaging process

THE PERFECT MATCH

6+6 and Vega, together, offer maximum versatility, speed up production, and optimise resource management. This tailor-made combination ensures flawless communication between the machines, reducing costs and processing times without compromising quality, even with the most delicate products.

DOUBLE EFFICIENCY

6+6 and Vega are the ideal combination to maximise your line’s efficiency and precision:

- Reduced labour costs: automatic feeding means fewer operators are needed, allowing for higher production in less time.

- Up to 90% giveaway reduction: the combination weigher delivers ultra-precise doses, reducing excess weight tenfold compared to a manual scale.

- Lower processing costs: fewer workers and significantly less giveaway translate into much lower operating costs.

- Boosted productivity: with lower costs, minimal product giveaway, fewer processing issues, and more packages produced in less time, your line’s performance soars.

Come find out 6+6 and Vega at FRUIT LOGISTICA, Hall 2.1, Stand B-11!

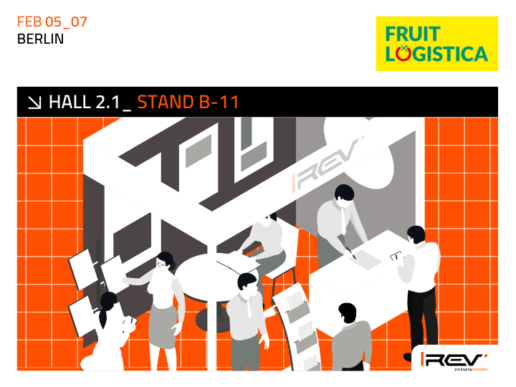

REV awaits you at FRUIT LOGISTICA 2025

FRUIT LOGISTICA 2025: FRUITFUL CONNECTIONS

From 5th to 7th February, the must-attend event for fresh produce and related packaging machines returns: FRUIT LOGISTICA, the global benchmark for the industry.

As always, REV will be here: Hall 2.1, Stand B-11. 6+6 and Vega will also be there – which is the perfect combination to automate weighing and netting while ensuring maximum versatility, precision, and delicacy – along with much more.

There’s truly something for every need! Stay tuned for more details.

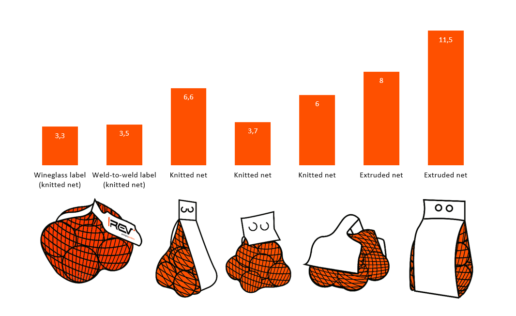

P-Packs: thermosealed nets with wineglass or weld-to-weld label

The monomaterial alternative to metal clip

In REV, we boast a long experience in hot sealing and, for years, we have been committed to environmental respect. An example of this is provided by Puma, packaging machine for thermosealed nets which creates a 100%-recyclable monomaterial packaging consisting of tubular net.

But there is more: unlike most thermosealing packaging machines on the market, Puma applies to the package a tape functioning as an handle and a label, wineglass or weld-to-weld (sealed at the extremities). Furthermore, the machine is equipped with a thermal-transfer printer capable of printing all product information directly on the label.

The label, customisable is shape and size, offers then a wide space for communication and guarantees an attractive and appealing package. All of that, simultaneously saving a significant amount of material: overall, Puma’s P-Pack is made with 50% less plastic than classic thermosealed bags!

Designed several years ago and optimised over time, Puma provides a valid alternative to metal clips without compromising on weight or packaging costs and ensures the efficiency of years of development and testing.

Puma is born with the aim of a recycling that may be economically sustainable and accessible to everyone, and not only to countries with the most advanced disposal facilities. It is therefore essential to create a monomaterial packaging.

Puma wins the challenge of replacing the metal clip with a solution that guarantees a packaging that is equally simple and lightweight, and therefore cheap for both the packager and the consumer, and has a lesser impact on the planet!

6+6 Rotopack: production has never been this easy!

No giveaway, no waste, with 6+6 Rotopack

Here is our super new solution!

6+6 Rotopack, ultra-gentle weigher with packaging station, has been projected for maximising profits by operating on two different levels simultaneously.

The weigher itself, designed for preparing doses according to a pre-arranged (and never lower) weight, reduces giveaway to a minimum.

Rotopack, on the other hand, introduces some simple but practical measures intended for optimising production by facilitating the work of the operator, which will have to take care only of a specific phase of the filling / packaging, saving time and energy.

Come discover 6+6 Rotopack at Fruit Logistica, from February 7th to 9th, Hall 2.1, Stand B-11!

FRUIT LOGISTICA 2024

The heartbeat of the fresh produce business returns!

Right after SIVAL, all together to Berlin! From February 7th to 9th, it returns FRUIT LOGISTICA, the heartbeat of the fresh produce business!

Almost everything is set, the event program is online and a record number of exhibitors is expected. As always, the focus is on innovation and technology, especially regarding the area dedicated to packaging machines.

And, also this year, REV awaits you at Hall 2.1, Stand B-11, with exclusive news… See you soon with further details! In the meantime, have you saved the date?