Record numbers for packaging machines

2022 to an end: the sector takes stock

The whole world is in environmental, pandemic, war-related and economic crisis. Nevertheless, 2022 closes really positively for Made-in-Italy packaging machines, which widely surpass pre-Covid performances.

With a 8,2-billion turnover and an export which amounts to nearly 80%, Italy confirms its leadership in the production of packaging machinery, especially for food and beverages.

After all, the business volume related to the packaging solutions for the food & beverage industry, which in the past two years already proved to be the driving branch, is globally worth 15.3 billion euros, with a 2.1% expected annual growth within 2025.

These data depict a scenery which is almost incredible if we consider that the industry had to face the pandemic and, thus, components which are difficult to find, delays and ever-higher costs first of all, and then the Ukrainian war and the resulting increase of energy prices and row materials.

And the fruit and vegetable sector in particular had to deal with quite-complex challenges: in fact, Eastern markets closing has worldwide rearranged trade flows, redirecting in Europe more or less 4 million tons of fruit and vegetables, causing an excess supply and a strong price pressure on local products.

But the sector not only held up, but it also excelled, investing in digitalisation, automation, mechanised processing and in innovation aimed at the ecological transition which, we all agree, can’t stop, must remain our priority. That is what Nomisma says: sustainable companies register a revenue 10% above average.

In conclusion, exactly as the vice president of UCIMA, the association of Italian manufacturers of automatic packaging machinery, wishes: “Made-in-Italy packaging, as world leader and pioneer of the development of sustainable solutions, has everything it takes to become the motive force for a green transformation of packaging materials and technologies on an international scale”.

The last two years speak clearly: paper and cellulose are the macrotrend of the moment

A new life for Vega

More and more frequently, in all areas of the public and private spheres, we hear about “sustainability”. What is it, exactly? For what concerns the food-packaging sector as well as more in general, “sustainability” certainly refers to “the capacity of a production-and-consumption model of meeting the needs of the present without spoiling the ability of future generations to meet their own needs”, to quote the former Norwegian prime minister, in addiction to mean, in the age of the revision of value chains in a green perspective, competitive advantage.

And for those buying, the sustainability score of the product also depends on its wrapping, which should be according to 62% of those polled by Nomisma’s Osservatorio Packaging del Largo Consumo recyclable, for 59% realised with environmentally friendly materials and, for 46%, with no excess grammage. “The awareness that a diet is healthy not only when is nutritionally adequate, but if it promotes human wellness and respects our planet, begins to spread”, says Slow Food Italia’s president, Barbara Nappini.

Thus, sustainability, but not at the expense of safety and of the product quality, which still remain important purchasing drivers and that are the reason why, in a scenario in which labels are synonym of a brand guarantee, and in which, as Marco Pedroni, president of Coop Italia remind us, “bringing loose produce on supermarket counters requires great efforts in terms of logistics and refrigeration, with an equally heavy impact in terms of emissions”, “packaged” is still preferable to “loose”. And speaking of environmentally friendly materials, according to common believes (more precisely in 41% of the cases), plastic free corresponds to ecological.

European legislation itself moves towards this direction: in France is already in force the prohibition of using polymers for packages of fruit and vegetables under 1,5 kg and soon, starting from 2023, Spain will adopt the same regulation.

Simultaneously, large-scale distribution too has to face environmental-protection issues and, globally, it has definitely been chosen the path of plastic reduction, when possible.

In such a context, our Vega, horizontal netting machine launched in 2015, is experiencing its period of maximum splendour.

Significanlty ahead of its time and now renewed in its graphical interface and optimised for satisfying 4.0-Industry requirements, Vega has been projected for creating different types of package of loose items such as fruits, citruses and vegetables up to 2 kg, as well as in punnets, trays and small cartons, by using woven or extruded net, in cellulose and natural fibres too, with a wineglass label, also in paper.

The net is then closed at the extremities with a metal clip which, currently, represents the only possible solution for cellulose. Undoubtedly, monomaterial packages are the goal to aim at and, of course, on the market there are bags in thermosealable paper, but it is necessary to remember that the wrapping must ensure a great visibility of its content, besides being sustainable and practical, for sure.

Taking into account all different necessities that the packaging is called to respond to and the limits set by the technologies we have, the metal clip constitutes the best compromise, especially considering that the consumer must be required the minimum effort in making use of the goods and in managing waste: the clip is easily removable from the package during differentiation and, above all, during recycling in disposal and recovery facilities!

A joint effort for countering global warming

COP27 at the start

On 6th November, in Sharm el-Sheikh, it has begun COP27, the twenty-seventh United Nations Climate Change Conference.

At the centre of next weeks’ debate, themes which are particularly dear to us at REV: the reduction of greenhouse gas emissions, at the basis of global warming, and, more in general, the search of more effective and incisive sustainability models.

Basically, the action plan developed by ONU is divided into four points, separated and still closely related to each other: mitigation, adaptation, financing and cooperation.

The goal is always the same: to maintain the temperature increase within 2 degrees Celsius, aiming at 1,5, as well as, of course, to find pragmatic measures to deal with the current state of affairs, especially for what concerns more fragile and vulnerable realities, Africa first of all.

And all of this will be possible only by annually allocating an amount of funds appropriate to the extent of the crisis, that is to say, on average, more or less sixfold more than what invested so far.

The road is long and winding and the objectives really ambitious, hence, an inclusive and active participation of us all is needed, above all at institutional level, but in the production process and individually, in everyday life, too.

REV, since ever, is committed to limit the packaging environmental impact and to design solutions that are not only highly productive, but which also best combine performances and ecology. Find out in detail our contribution to the cause: https://www.revsrl.com/en/sustainable-packaging-innovation/

Eco-solutions for a concrete circular economy

REV Packaging Solutions launches a new challenge: who will take it up?

Even though there is much left to do for carrying out the ecological transition already started in the early 70’s (and maybe only a miracle could save us from the climate crisis that we are going to face), we certainly took some timid steps forward.

Everywhere, is spreading a prevention culture in terms of environmental protection which has re-calibrated consumers’ moral compass and which brought new behavioural patterns intended to provide a pragmatic and effective response to the sustainability issue: evolution cannot prescind from environmental debate anymore, everyone wants (and has) to do its own part.

Last market researches highlight how, when choosing what to buy, in everyday life, besides the product quality (which remains constant at the top), a new variable enters the game: the environmental impact of the product and of its packaging and the negative effects that they will have on the planet.

More than 90% of the buyers is attentive to the ecosystem and to its protection. But there is more: according to recent statistics conducted by Comieco (National Consortium for the Recovery and Recycling of Cellulose-based Packaging), the perception the buyer has of a brand is increasingly strictly related to the sustainability of the product packaging and, in particular, to the ease of interaction with it, from its opening, up (and above all) to its disposal.

Something has changed but, for putting revolution into effect, visibility is required. And that is when large distribution comes into play: for dealing with the new eco-packaging demands, it is necessary to propose consumption models that correspond to the real needs of the customers and the community as a whole and which may allow, thus, a more conscious use.

And, after all, this is exactly the willingness to change that we builders have been wishing for (and on which we have been working) for years. But, how to proceed? First of all, it will be necessary that more and more production realities invest on new technologies and materials, which may be really sustainable. Then, overpackaging must be avoided and the range of biodegradable and compostable materials extended, of course. But, what makes a packaging for food use ideal? Firstly, it has to respect the product, by guaranteeing it high protection and preservation levels, by giving it great visibility and by conveying all necessary info, from the origin up to sales support. And from the point of view of food conservation, it is undeniable that plastic packagings still are the most functional ones, in most cases. What to do, thus? There is only one answer: monomaterial plastic.

Because if it is true that consumers’ sensitivity has increased with respect to separate collection, on the market there are still too many plastics coupled with other materials or with other types of non-recyclable plastic which, even worse, are often praised as the future of the industry. Coupled plastics may seem to be more high-performing during use but, at the end of their life cycle, are not reusable, in any way. On the contrary, a circular-economy project is based on the life prolongation of the packaging, not to mention that packages made of different materials, even when partially recyclable, are deceptive and, in any case, are not practical for consumers.

Monomaterial plastic (of wrappings, clingfilm and packages of different kinds), on the other hand, is easily disposable for both the final consumer and those companies deciding to invest in green solutions and, above all, can be reborn and become a new packaging able to ensure great performances.

It should also be considered that, currently, while paper is certainly recyclable but not reusable for food use, monomaterial plastic can be recycled (almost endlessly) keeping intact its properties. Therefore, if correctly recycled, plastic has a lower environmental impact with respect to any other material generally used for fruit-and-vegetable packaging, besides guaranteeing, this way, economic and environmental benefits.

At REV, committed to designing solutions for all types of specific needs, for years we have been realising machines for creating a monomaterial and totally recyclable packaging.

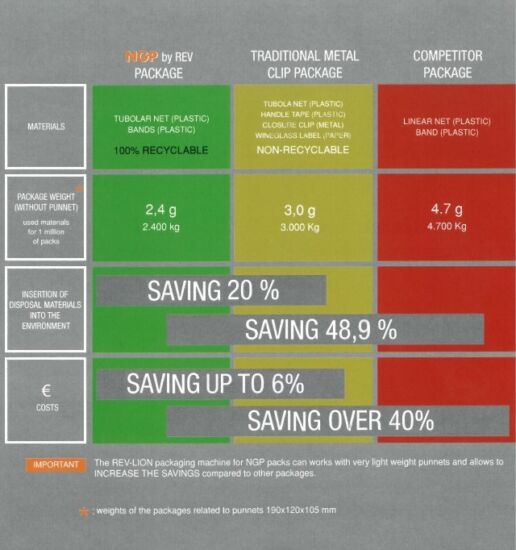

This is exactly the case of the netted punnets produced by Lion horizontal packaging machine in which, since 2010, the thermosealing technology substitutes the metal clip. The NGP-package innovation is represented by its perfect synthesis of economy and ecology (less plastic means lower costs for both the production and the disposal and a lower environmental impact), without compromising on the punnet aesthetic or functionality (on the contrary, the communicative space of the label has been improved compared to traditional packages). More specifically, NGP punnets have 20% less material with respect to metal-clip packages and 50% respect to our competitors’ similar punnets and, thus, ensure a 6% and 40% saving, respectively.

Other examples are Tiger, vertical packaging machine which eliminates the metal clip from packages of loose products in line, and Puma vertical netting machine that, besides realising 100%-recyclable packages (in bag or line) with no metal clip, like Tiger uses up to 50% less plastic compared to our competitors’ machines. Moreover, with all machines taking advantage of a thermosealing technology produced by REV, it is possible to use certified compostable materials (OK compost), instead of recyclable plastics.

In sum, at REV we believe we all need a new approach to sustainability issue: a real investment in terms of time and projectuality is necessary. Of course news imply some risks but, even economically, the passage to monomaterial can only be beneficial, for packagers too. Those which have the power trigger thus the mechanism: this is REV’s appeal to the GDO and its invitation to join forces in this race against time. Keep in mind that “progress is impossible without change” (George Bernard Shaw) and that, above all, there is no planet B! Who will have the courage to make the first move?

Once again, to Berlin!

FRUIT LOGISTICA 2022: all set for departure

From 5th to 7th April it returns Fruit Logistica, the annual appointment with all news concerning the international trade of fresh produce and related services. The event, which globally represents a key point for the entire food-processing-sector supply chain, from production up to transformation and distribution, offers companies, buyers and suppliers from all over the world the opportunity of interfacing with each other and exchanging views on the future of the industry and of presenting their own idea of innovation.

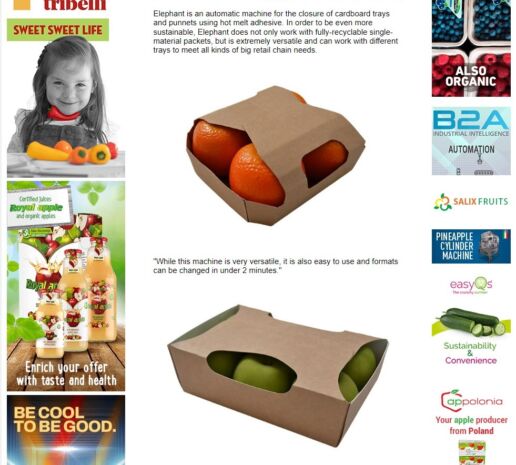

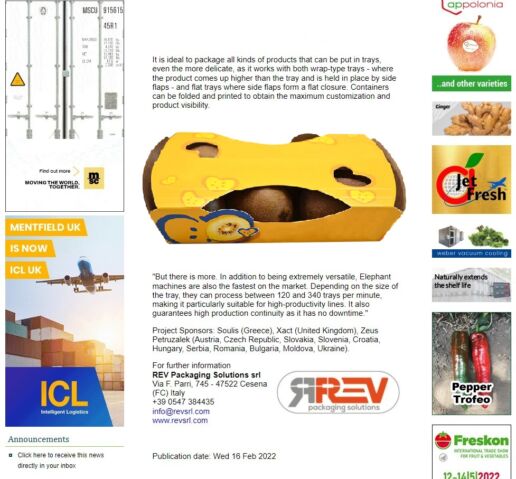

Also this year, thus, REV brings to Berlin its sustainable-development project. Come find us at Hall 9, Stand A-04 to discover Elephant, our super new closing machine for cardboard trays (either flat or corrugated and, possibly, in other materials too) with side wings (also asymmetrical), capable of working any product usually contained in trays, including most delicate ones and of realising monomaterial packages, wrap or flat type, by means of a hot-glue system, and doing it in the fastest possible way (Elephant is, indeed, the fastest and most versatile closing machine on the market), and to re-discover Puma, thermosealing netting machine which creates a packaging with no metal clip, compostable and 100% recyclable or with 50% less plastic.

FreshPlaza tells REV’s projects for a sustainable development

Environmental-protection packaging and innovation: a few examples

This week, FreshPlaza talks you about REV and our mission: among the first in the fruit and vegetable sector to take up the “green challenge”, without losing sight of the requirements of the large-scale distribution, constantly looking for ever-more eco-friendly and attractive wrappings, and of the packagers of maximising the packaging processes, for years we have been projecting complete solutions, ad hoc too, ecological and sustainable.

Our Lion, thermosealed-punnet netting machine, is able to realise a 100%-organic packaging or in-plastic one but by using 50% less material with respect to our competitors’ packages.

Our thermosealing netting machines Tiger and Puma eliminate the metal clip and realise monomaterial packages, compostable and 100%-recyclable, or with 50% less (recyclable) plastic.

Vega and Spider, clip netting machines, in addition to recyclable plastics, can work with natural-fibre organic materials.

And again, in the wake of Eagle and Condor, automatic machines 350% faster than existing manual solutions, of Hollywood filming machine which, working more crates at once, doubles the production, or of Bison and Series A weighers that, besides guaranteeing more gentleness in treating the product, ensure 20% more production compared to the previous versions, Elephant, our new closing machine for cardboard trays with side wings, creates monomaterial packages and, thanks to its ultra-high performances (it is the fastest on the market) and its extreme versatility (it is suitable for all products usually contained in trays), is already achieving great success.

FreshPlaza presents Elephant

The prestigious magazine FreshPlaza illustrates REV’s latest creation

FreshPlaza is the portal leader in the fruit and vegetable sector, with news, advertisements, marketing researches and analysis, reports and much more. What better springboard, thus, for Elephant?

The international bulletin dedicated to the world of fruit and vegetables talks about our closing machine for cardboard trays and crates with side wings, the fastest on the market, capable of realising monomaterial packages (in flat or corrugated cardboard, wrap or flat type), totally recyclable and suitable for a really wide range of products. Find out everything about Elephant: https://www.revsrl.com/en/portfolio/elephant-closing-machine-for-cardboard-trays-with-wings/.

SIVAL 2022: agroecology at the service of the planet

REV responds to SIVAL’s call

After the period of forced stop of the last years, the world of agriculture and the sector professionals are ready to restart at full throttle…by using renewable energy! But restart from where? From Angers, France, of course. It could not be otherwise: the capital of the Maine-et-Loire department, for over two centuries, has been representing one of the main cultivation centres of plants of any type, from fruit, vegetables and vines, to trees and shrubs, passing through seeds and medical and aromatic herbs.

The fair, which is internationally emblem of innovation inside the agricultural sector and which, for years, has been setting itself the ambitious and noble goal of shortening the distance between maximisation and sustainability, is constantly searching for modern technologies intended to safeguard and protect the environment.

REV, that fully shares SIVAL’s mission of a transition towards a circular economy that may be as quick as possible, makes its contribution: its super new and fast closing machine for cardboard trays with wings, capable of realising monomaterial and thus 100%-recyclable packages. Come find out Elephant from March 15th to 17th, 2022, at Angers Expo Congrès Parc des Expositions, Hall B-A-108.