Puma 4th generation: production never stops

Always in motion

In fresh produce packaging, every machine stop means lost time and organisational challenges. The fourth generation of Puma has been designed to minimise interruptions, ensuring smooth and continuous production throughout the shift.

Fewer stops, more efficiency

Daily operations that previously required a machine stop can now be performed without interrupting the production cycle: tube change takes place without stopping the machine, cooling water and handle can be refilled from the outside, and the machine has no doors, it is equipped with safety barriers instead, ensuring even faster access. The result is a more stable line, with fewer micro-stoppages, and predictable, reliable output.

Simplicity for operators

Puma 4th Generation is designed to simplify operators’ work: fewer manual interventions mean greater control over the process.

Consistent performance over time, and production takes off

With Puma, the priority is not peak speed, but maintaining consistent performance. This translates into real efficiency, uniform quality, and peace of mind for operators, ensuring production never stops, in fact, it takes off!

Come and discover the new version of Puma at FRUIT LOGISTICA, Hall 2.1, Stand B-23. We look forward to seeing you there!

P-PackⒹ becomes a registered EU model

Sustainability and functionality recognised

P-Pack is now protected as a registered design at European level, an important recognition that highlights its distinctive shape, including the handle and the two types of label, as well as its record-breaking grammage. And now that it is official, we can tell you more about why P-PackⒹ truly is a revolution (without forgetting tradition).

A solution born from real needs

P-Pack was developed following a design approach focused on functionality and material optimisation. Its structure was designed to reduce the overall weight of the packaging while maintaining ease of use, product visibility and adequate space for information. All this without altering the shape of traditional clip nets: in fact, P-Pack retains all their advantages, while being completely monomaterial and recyclable.

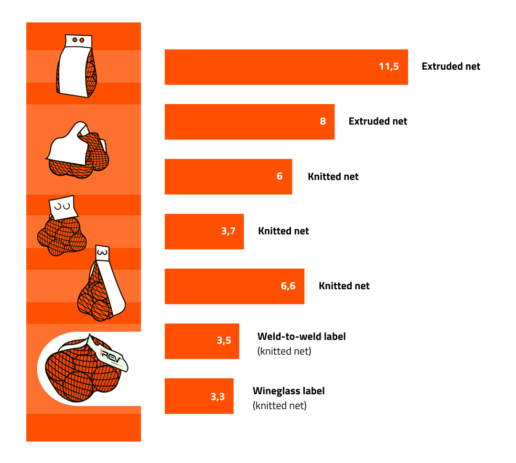

What sets it apart from other thermosealed nets

Compared with similar solutions currently available on the market, P-PackⒹ offers tangible advantages:

- at least 50% less plastic, making P-Pack the leading solution in terms of sustainability among thermosealed nets for fresh produce;

- an ultra-thin yet spacious label, making the packaging even lighter without compromising functionality or aesthetics;

- a handle that makes the package particularly convenient to carry and handle.

Looking ahead

Design protection meets the need to safeguard a solution that has stood out over time for its technical features and design approach. With P-PackⒹ, there is no need to compromise between practicality and sustainability: the future of net packaging is already written.

To see P-Pack live, come and visit us at FRUIT LOGISTICA, Hall 2.1, Stand B-23. We look forward to seeing you!

FRUIT LOGISTICA 2026

New location for REV and more news ahead

Once again this year, REV confirms its participation in the leading international event for the fresh produce sector and for fresh produce packaging solutions. Of course, we are talking about the highly anticipated FRUIT LOGISTICA, taking place in Berlin from 4th to 6th February.

For the 2026 edition, REV will be moving to a new location. Where can you find us? Hall 2.1, Stand B-23, just a few metres away from our previous position.

That said, you can expect the usual things, along with a few unexpected surprises: the same innovation, the same cutting-edge technology and… unprecedented production continuity!

What to expect

During the event, visitors will be able to discover all the details of P-PackⒹ, the world’s number one thermosealed net in terms of economy and ecology, and much more besides. Visit us at Hall 2.1, Stand B-23 to see live our brand-new solution, designed to ensure highly efficient, uninterrupted workflows… and let production take off!

A very quick recap

📌 FRUIT LOGISTICA 2026, Berlin

📅 4–6 February

👉🏻 Hall 2.1 – Stand B-23

KEEP PRODUCTION RUNNING!

SIVAL 2026

Vega will be the main focus

Everything is ready: from 13th to 15th January we will be attending SIVAL 2026, the leading international trade fair for solutions dedicated to the fruit and vegetable sector, once again held in Angers.

Together with Filpack, we will be presenting live a true classic: the clip netting machine that, more than ten years after its launch, is still able to meet every market requirement and perfectly represent our design philosophy: maximum versatility without compromising on performances.

We are, of course, talking about Vega.

Why Vega

Over the years, Vega has successfully adapted to different markets, products and packaging materials, while keeping its core strengths unchanged: not only operational flexibility, but above all gentle product handling, efficiency and high processing speed.

Designed for packaging loose products up to 2 kg, Vega can also handle particularly delicate produce, working with a wide range of materials, from plastic nets to cellulose and natural fibre nets. To complete the package, it can apply label (including in paper) and handle, also customised.

Format changes are extremely simple as well: since no mechanical adjustments are required, downtime is kept to a minimum and production efficiency takes off!

Where to find us

Come to SIVAL 2026 to see Vega in action and discover all the details. We look forward to welcoming you together with Filpack at Hall B, Stand D-75.

From circular layout to linear layout: a new packaging bench for 6+6

Linearpack has born, a new linear packaging station

The core concept behind 6+6 remains unchanged: a system designed to minimise waste and optimise the composition of each dose. With Linearpack, this principle is reinterpreted in a linear layout.

Order, quality control, rhythm: same philosophy, different flow

Linearpack organizes work in a structured, precise, and repeatable way, ensuring maximum product quality control. However, the linear arrangement, combined with intermittent movement, reduces operators’ movements and makes the workflow even smoother than with Rotopack.

Ergonomics become central: more operational space, fewer manipulations, and a smoother work sequence allow operators to work more comfortably and efficiently. The result is a line designed to support even higher productivity levels.

Advantages of the linear layout

The clear separation between weighing and packaging phases allows each operator to focus on a specific task, reducing errors and idle time.

Thanks to its design, Linearpack can also be integrated with an automatic punnet denester, a key element for managing higher production flows.

In short, if Rotopack set the pace in limited spaces, Linearpack pushes it forward along a line designed for speed, ergonomics, and productivity: two interpretations of the same concept, offering targeted solutions for different production contexts.

Summer break ahead

Closed from August 11th to 15th, but technical support guaranteed

This year, REV is also taking a few days of sun and relaxation, but don’t worry: it won’t even be time to say “summer” before we’re back with you.

From August 11th to 15th, our offices and production will be closed for a very short break, but we know well that emergencies never take a holiday: even during the closure, you can count on our assistance service!

Our technicians will be available from August 11th to 14th, every morning from 8:00 a.m. to 12:00 p.m. You can contact them here:

📞 +39 340 475 1944 / +39 340 291 7268

We’ll see you soon and, in the meantime, happy holidays to those taking a break

Packaging and Packaging Waste Regulation (PPWR)

What will change from 2026 for packaging and its disposal

In February 2025, the PPWR, Regulation (EU) 2025/40 on packaging and packaging waste, entered into force.

The regulation updates and complements the previous texts with some new provisions.

A step back: environmental labelling from the beginning

Environmental labelling, meaning the obligation to indicate the composition and methods of reuse and recycling on all packaging, has been discussed for decades.

This very sensitive issue has been addressed repeatedly:

- Since 2006, it has been mandatory to identify the material each package is made of, to provide clear instructions for recycling.

- In 2020, these indications were required to become clearer and more transparent for consumers as well, theoretically introducing a note on how to dispose of the packaging or an invitation to check with local regulations.

- In practice, however, disposal instructions were postponed multiple times and only became fully mandatory in 2023.

- So, what happens in 2025?

The new developments introduced by the PPWR

The 2025 PPWR establishes that labels must be standardised across the EU – a major step forward for consumers, who currently face unclear and inconsistent information.

To overcome the space limitations of physical labels, a digital format will also be adopted, which is QR codes to provide all relevant details.

From 12 August 2026, once the European Commission has defined (and hopefully explained) the standards of these harmonised labels, all packaging producers must comply with initial goals:

- demonstrate the exact composition of their packaging;

- reduce excessive weight and volume (no more than 50% empty space inside the packaging);

- eliminate hazardous substances from packaging and recycled materials;

- begin applying the principle of design for recycling, which requires that by 2030, all packaging on the market must be at least 70% recyclable.

Penalties will already be applied from 2026 for non-compliance with the initial objectives. In 2028, Harmonised and Digital Labelling will officially come into force, although a transition period will allow companies to sell off existing stocks.

But that’s not all: from 2029, in countries where recycling targets are not met, deposit return systems will be introduced to encourage the recycling of plastic and metal beverage containers.

And again, regarding plastic...

There is still talk of banning single-use plastics, even for unprocessed fruit and vegetables under 1.5 kg.

While this ban makes perfect sense for some products, it’s not appropriate for fresh produce.

Products that will definitely be banned include: ultralight plastic bags (unless used as primary packaging), baggage wrapping at airports, packaging for food and drinks consumed on site in hotels, restaurants and bars, disposable plates, cups and cutlery, and single-use cosmetics in the hospitality sector.

As for fruit and vegetables, no need to panic for now: each Country will define when plastic is strictly necessary for hygiene and safety reasons, and to avoid food waste. This principle will certainly apply to meat, cold cuts and fish – and hopefully also to tons of fruit and vegetables that would otherwise end up in the bin.

Checkweighing gets a blast with Dyno

Utmost precision at full speed

What is Dyno?

Dyno is a dynamic checkweigher designed to verify the weight of packaged products in motion, without stopping the production line.

The benefits of using a checkweigher

Checkweighing is not just a legal matter: it’s not only about complying with regulations that require declaring a minimum package weight, but above all, it’s beneficial for you!

Why give away your product when you can monitor and verify the exact weight of every single unit? Using a checkweigher is a great advantage for everyone – packagers and consumers.

Why choose Dyno?

Dyno’s technology is based on a weighing system with an optional separate diverter that eliminates vibrations on the scale, ensuring extremely precise measurement at any processing speed.

Moreover, Dyno is ultra-quiet, aesthetically really elegant, ergonomic and easy to use thanks to the touch-screen panel that simplifies the management of operational parameters. But there is more.

Built to last and offer the highest hygiene standards

Dyno is solid and robust, built with state-of-the-art components particularly resistant to wear, and features an IP65 protection rating that makes it very easy to sanitise.

Maintenance is also simple and immediate: the conveyor belts are removable without tools and every part is safely accessible.

What does this mean? Dyno is simply ideal for industrial environments where hygiene and durability are a must!

Freskon 2025: we were there, even if we weren’t

Thanks to those who thought of us

Freskon 2025 has just wrapped up, leaving behind three days full of meetings, exchanges and new developments in the world of fruit and vegetables and its packaging.

Unfortunately, we couldn’t attend in person this year, but we were there in spirit – thanks to our partner Soulis, who, as always, represented us at their best.

Many of you stopped by their stand, shared thoughts and ideas, we were told. We are truly grateful to everyone who thought of us, even from afar.

For now, we leave you with a few snapshots straight from Thessaloniki: even if we weren’t physically there, we definitely feel part of this edition. See you next time, Freskon!

Freskon 2025

A dive into the innovation of agricultural practices and packaging for fruits and vegetables

With the arrival of spring, the attention of fruit and vegetable industry professionals turns to Freskon. But what is Freskon?

Since 2015, Freskon, in Greece, has established itself as the leading trade fair for the fruit and vegetable sector in the Balkans and Southeastern Mediterranean, becoming a strategic bridge between companies involved in the distribution of fresh produce and global markets.

What to expect at Freskon 2025

Attending Freskon means immersing oneself in innovation. The fair provides a comprehensive overview of current and future market trends, along with valuable networking opportunities with participants from around the world.

This year’s edition, in particular, promises a rich and diverse program, featuring events and workshops dedicated to agricultural practices, preservation, packaging, commercial insights, and consumer behaviours.

Useful information

The event will take place at the Thessaloniki International Exhibition & Congress Center from April 10th to 12th, Thursday and Friday from 10:00 A.M. to 7:00 P.M., and Saturday from 10:00 A.M. to 5:00 P.M.

Once again, our partner Soulis will represent us. You can find them at Hall 15, Stand C01: come discover what we have prepared for you!